25mm Press Cap Mould Hand Sanitizer Bottle Flip Top Cap Injection Mould

The business keeps to the operation concept 'scientific management, premium quality and efficiency primacy, customer supreme' for Plastic Lids Compression Molding, Pet Bottle Cap Making Machine, Lids Compression Molding Making Machine. Situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We promote team innovation and continue to conduct various exchange activities, hoping that everyone will be able to move forward with the company. We will provide high-quality, high-performance products and quality services for all partners.

Plastic Bottle Press Molding

Overview:

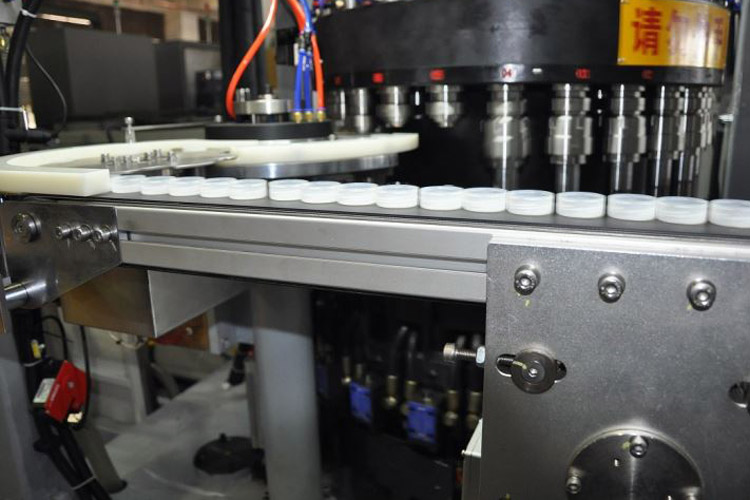

Bottle cap printing machine is equipped with automatic elevator, which is able to store a large volume of caps and feed the correct number of caps into the unscrambler. Maintain a sustainable number of caps in the unscrambler. Automatic feeding system is composed of aluminum and stainless steel, monitoring the conditions of feeding tracks with sensors. It will stop feeding when it is full, or vice-versa.

Flame treatment of plastic cap printing machine is a standard option. Aim to increase the adheres ion of the ink by this surface treatment. Two sets of two-color offset printing head equipped with magnetic print roller, it can achieve color on color printing. Each print head can be individually micro-adjusted various directions. The special designed link tray is simple and convenient for installation, disassembly and clearing, also reduce ink loss in order to improve production efficiency.