[ Taizhou Shuanghao Plastic Mould Co., Ltd. ]

Research, Development and Production Cap mould

Shuanghao company is a professional bottle cap mold manufacturer, supplier and exporter. We have strong scientific research technology, professional R&D and manufacturing, and our cap mould are sold all over the world.

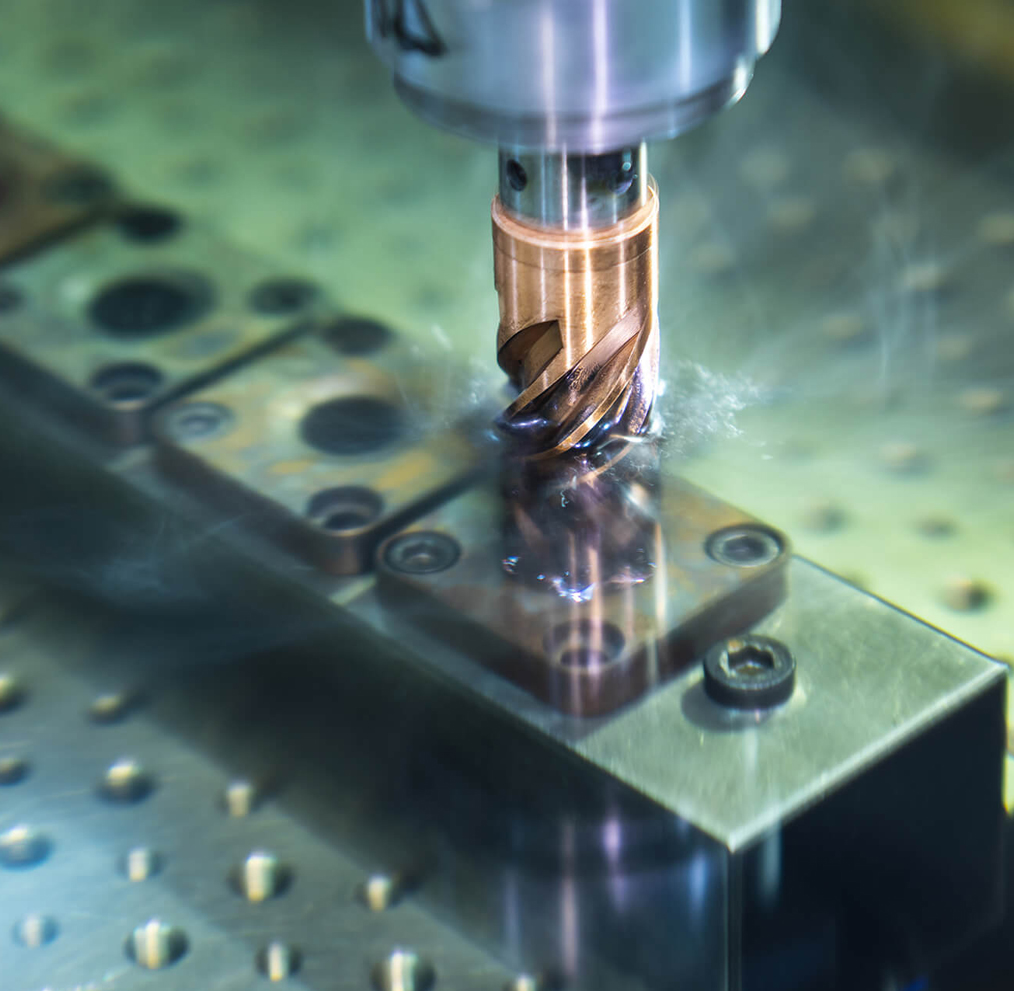

We manufacture injection moulds for qualified production of caps, dispensers and threaded closures. We have become leaders in the sector thanks to our deep know-how, advanced technologies and service ethics.

In the last 5 years the company’s production technology has been oriented towards the production of injection moulds for caps, dispensers and threaded closures of any shape and kind for high-quantity production, reaching the leading position both for unscrewing moulds and for flip top cap moulds.

[ OUR SERVICES ]

Construction of moulds.

[ how it works ]

FREQUENTLY ASKED QUESTIONS

Frequently Asked Questions?

Our products are mainly exported to over 30 countries such as USA,Germany,Japan,Spain,Italy,UK,Korea,Australia,Canada and etc.Our clients include many OEM customers who specialize in train,automobile,forklift and construction machinery,we already have had cooperation with more than 10 of the world’s Top 500 companies as one of their major casting suppliers in China.

Quality control of mould installation

We have own standard mould frame for cap mould and handle mould, we make complete inspection on mould to ensure the structure consistence and spare parts standardized. In addition, we will do independent standardization test on mould cooling system and hot runner system.

Product design and analysis

When we get samples or drawing of product, we always make all round analysis and inspection, such as moulding process feasibility, mould structure and movement feasibility, all the related plastic components matching situation, etc.

Mould design and analysis

With precise analysis, foreseeing rationality analysis for mould design, best processing analysis and mould structure application, it offers the most professional solutions with the most suitable mould performance and technical specification as customer required. The analysis include mold-flow analysis, mould ejection, cooling system, rationality of guiding system, application of mould spare parts' specification, customers' machine selection and special requirement application, etc.