Plastic Bottle Cap Making Machine Pvc,Pet Bottle Cap Slitting Cutting

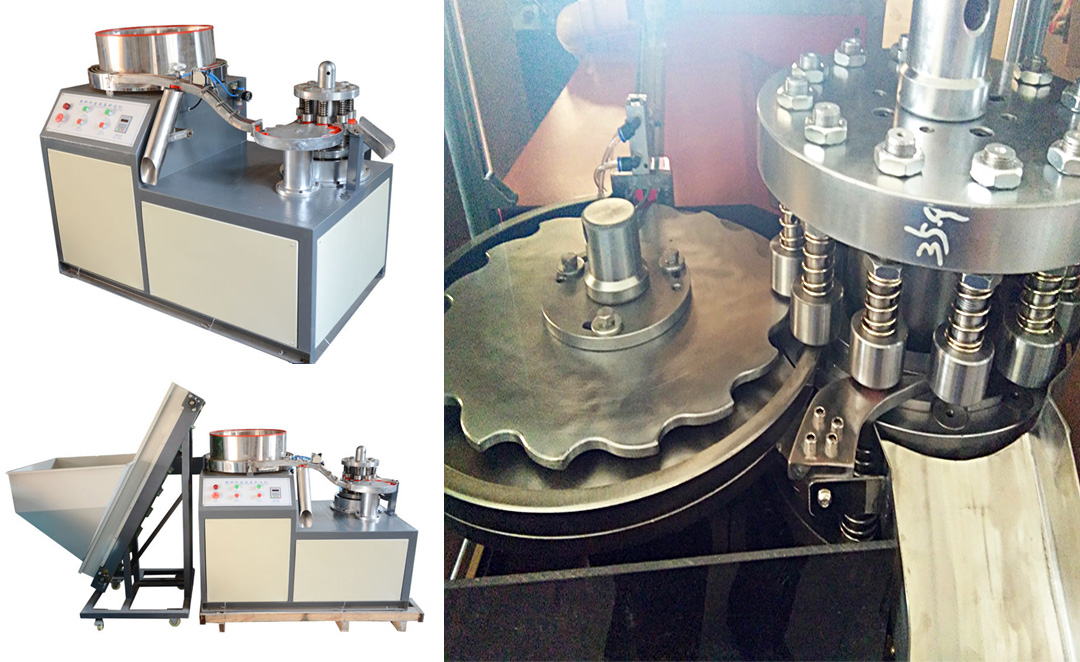

Shuanghao offers a line of user-friendly and efficient Automatic Cap Slitting Machine products for cap manufacturing in China. If you are looking to find a machine that can let you slit caps in a hassle-free manner, then you should use our Automatic Cap Slitting Machines for the best user experience.

Our Automatic Cap Slitting Machines have a simple interface that can be easy for you to navigate. With our Automatic Cap Slitting Machines, you can achieve speeds anywhere between 180 CPM and 350 CPM. You can have a perfectly precise slitting process whenever you work with these machines.

Key Specifications/Special Features:

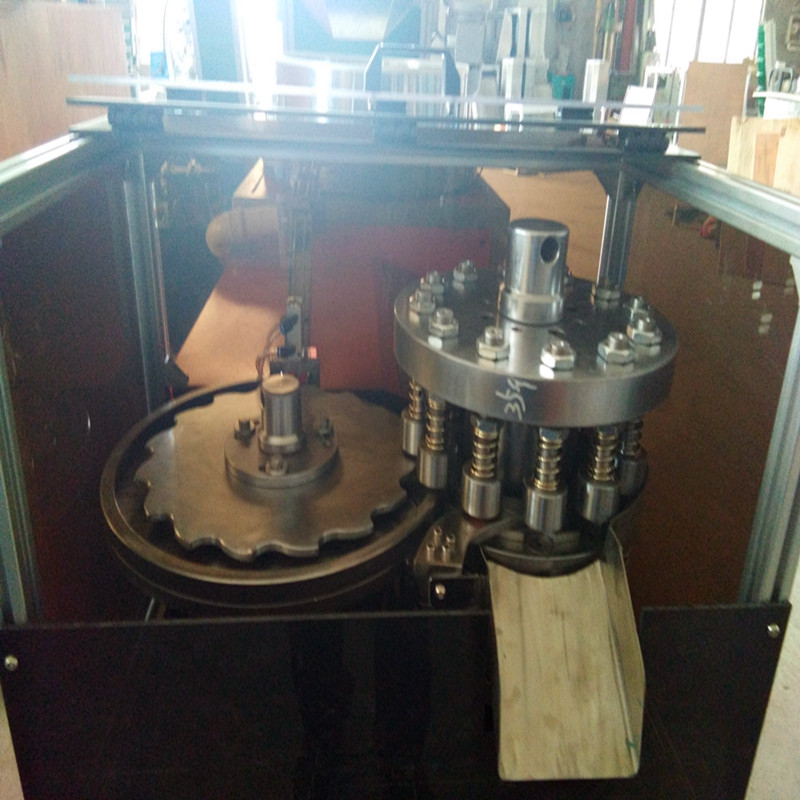

Cap compression molding machine is used to making the particles of plastic to the bottle caps of carbonated beverage and mineral water by high temperature plasticizing. When the plastic was out of the extruder, the Blanking plate will cutting the embryo and putting them into the molding chamber uniformly. The bottle cap making by this type of machine will be without injection gate and have excellent quality and beautiful appearance.

After repeated experiments, we have successfully developed the hydraulic bottle cap compression molding machine, which is got a set of hydraulic reciprocating transmission device and making the stabilize of the mold’s hydraulic transmission, low noise and convenient operation. In addition,this machine with a complete system of computer automatic temperature control and rotate speed matching between extruding machine and molding machine. The mold temperature and material temperature can be adjusted to best state, to ensure the durability and stability of the equipment.

This machine is simple operation, saving electricity, water, raw materials and labor. Compared with injection molding machine system of traditional craft have same energy consumption, the production can be growth to

three or four times. This machine not only won't produce waste runner,

and the mold of the cooling water and hydraulic oil are recycled, thus greatly reduces the system cost. Development to the success of the cap compression molding machine is making a breakthrough and innovation in the molding equipment.