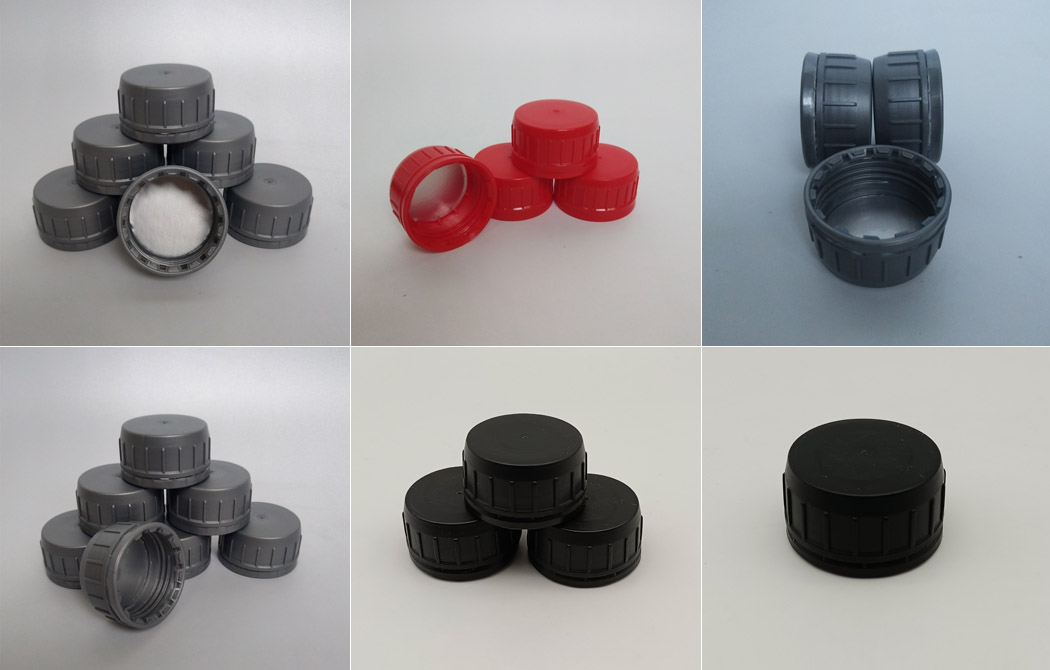

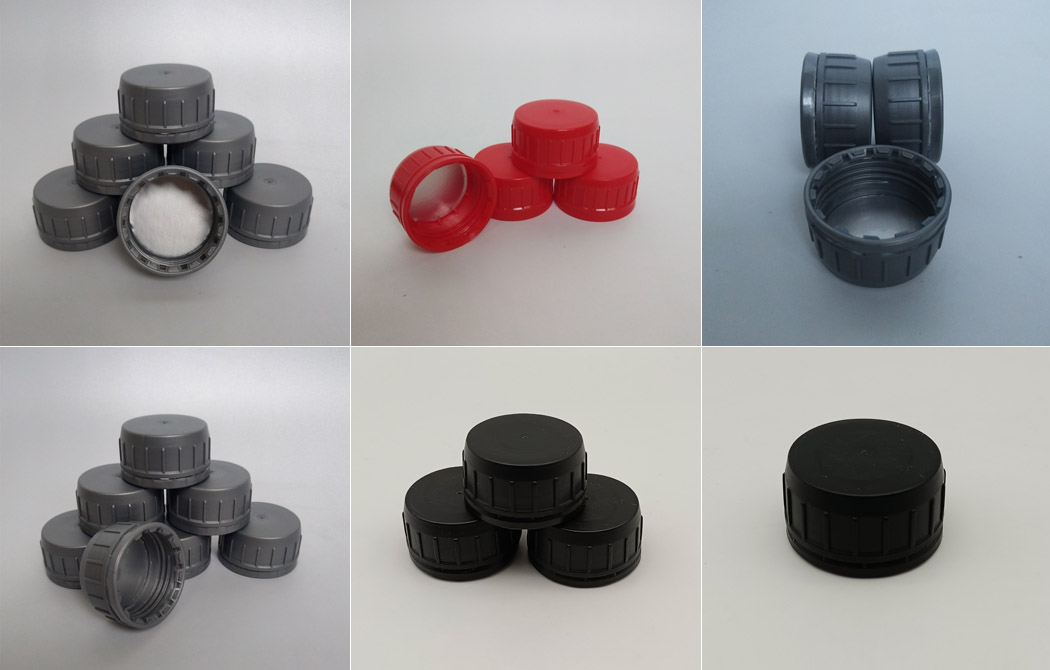

Customized Multi Cavity Diameter 42mm Plastic Injection Engine Oil Bottle Cap Mould

| Cavity | 1-72 |

| Mould base material | P20 , 45# , 4CR13 , .ECT |

| Core&Cavity material | S136,718, P20,2378,2316,4CR13,P20 .ECT |

| Runner | Cold /Hot (LOCAL BRAND,HASCO,YUDO,HUSKY .ETC) |

| Life time | 3,000,000 shots |

| Quick T1 time | 25-40 days |

| Package | wooden case |

| After Sale Service | Any mould problem,we will provide free maintenance service |

ADVANTAGE

1) Saving 10%-30% cost than others.2) Direct factory price3) Life:3, 000, 000 time4) 2D and 3D provided5) Quick T1 time: 25-40 days6) More than 15 years experience MOULD MANUFACTURE PROCESS

1)Cap Mould : grinding→fly-cutter →CNC Milling→drilling→lathe→boring lathe→electric pulse →fine fly-cutter→polish→electroplate→install2) Preform Mould: grinding→drilling→lathe→boring lathe→fine fly-cutter→polish→electroplate→install FLOW CHART| 1 | Sample or 2D,3D drawing from customer |

| 2 | Bulid 2D,3D drawing |

| 3 | CAD mould design |

| 4 | Send drawing to customer to confirm |

| 5 | Parts inspection/CNC machining/EDN machining |

| 6 | Mould assembly |

| 7 | Mould test |

| 8 | Send sample to confiom |

| 9 | Dilver the mould |

1. 2D&3D mold design (CAD, UG, Solidworks, ProE, etc, 2D drawing: DXF, DWG, PDF file, 3D model: IGS,PRT,X-T, e-drawing for free.)

2. Mold flow analysis report

3. Weekly report for progress

4. ISIR (Sample Inspection Report)

5. Mold trial, process sheet

9. Second operation such as oil spout, silk screen, pad printing and assembling

10.Packing & Delivery arrangement