China Bottle Cap Molds Explains The Preheating Skills Of Plastic Bottle Cap Molds

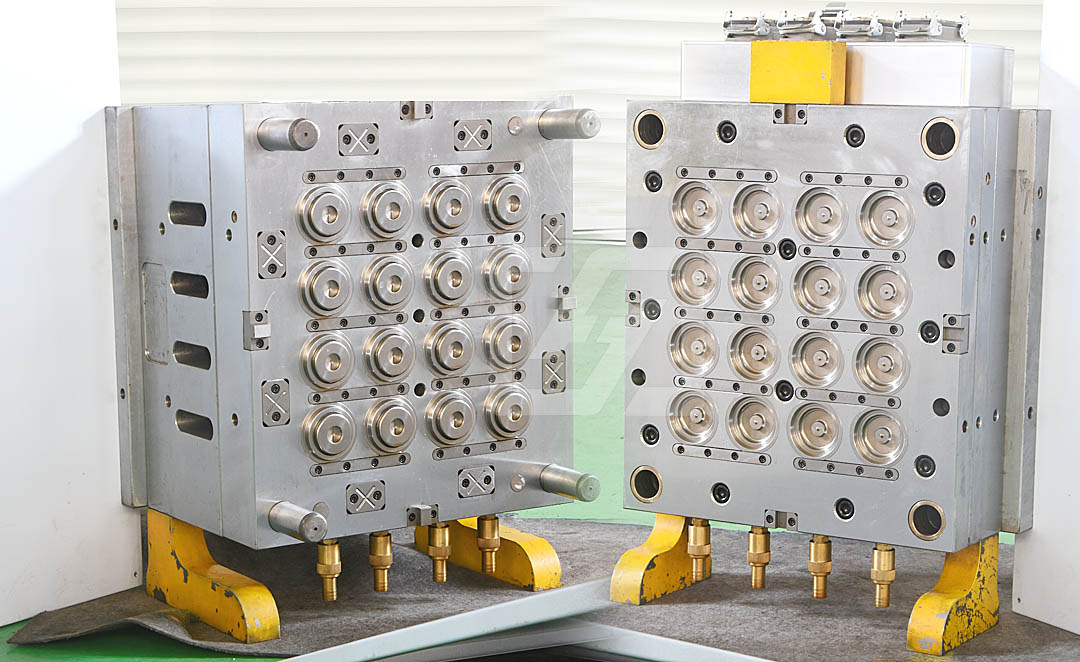

China has the reputation of "the hometown of molds" and has gathered many companies that produce preform molds, tube preform molds, and bottle cap molds. Among them, China Tebon Mould Co.,Ltd is a manufacturer specializing in the production of plastic bottle cap molds. Everyone is welcome to purchase bottle cap molds. Today, the manufacturers of bottle cap molds in China bring you the preheating skills of plastic bottle cap molds.

Next is the preheating skills of plastic bottle cap molds

1. Use the cooling water hole of the mold itself to pass in hot water for heating.

2. External heating method. That is, the cast aluminum heating plate is installed on the outside of the mold, and the heating is carried out from the outside to the inside. This method heats up quickly, but consumes a lot of heat energy.

3. For the plastic bottle cap mold, it can also be heated by the heat of the injection material.

There will be many problems encountered in the production process of large machinery, but some are just minor problems. We only need to fix them at the right time. The following are some guidelines that must be paid attention to when processing plastic bottle cap molds:

Do not allow the plastic bottle cap mold to have a lot of water during the processing, because if there is too much water, there will be no way to supervise the work; do not touch the wires; do not overheat, because overheating causes more than just product problems , There is also the issue of personal safety.

At the same time, we also hope that customers who purchase plastic bottle cap molds will pay attention to the above issues during use.