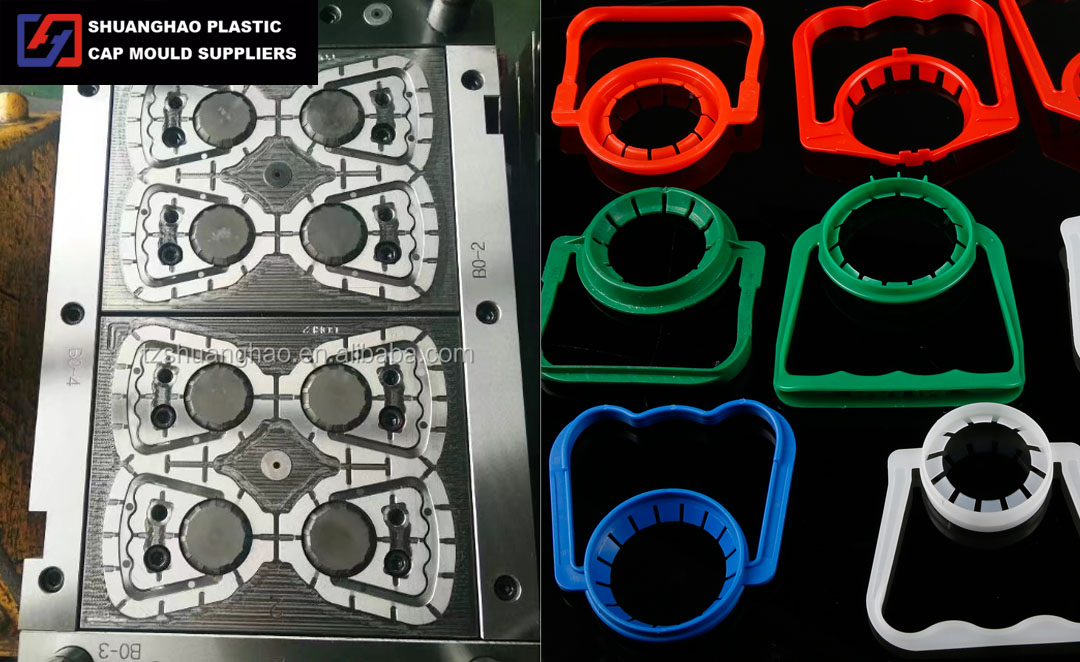

38mm 48mm plastic edible oil cooking handle molds-Shuanghao molds

38mm 48mm plastic edible oil cooking handle mould:

Plastic cap and handle moulds of "SH" company have high reputation in competitive price and high quality.

We have more than 20years experience to produce different kinds of plastic cap and handle moulds. The products from plastic cap and handle moulds are suitable for purified mineral water bottle, medicine bottle, beverage bottle, oil bottle, lampshade etc. We can produce any kinds of plastic cap and handle moulds in accord with customer requirement.

The features of our plastic handle mould: High quality with suitable price because we make the moulds based on the international standard and also high efficient processing machines. With the business idea of integrity,we considered what our customer thought and won the great public praise in client group.We get increasing number of old customers and many new customers who learned our brand, which is the reason why we can succeed.

| Product Name | 38mm 48mm plastic edible oil cooking handle mould |

| Core &Cavity Steel | 2316#steel, S136, H13, 718, SKD61, P20, S50C, 45#steel, 4Cr13, 3Cr13, BeCu or based on customer's requirement. |

| Mould base & Standard Component | DME,HASCO,MISUMI,LKM,Self-made etc. |

| Steel hardness: | HRC30-35 for base material. HRC45-48 for core and cavity material. HRC60-62 for special parts material |

| Plastic material | PP,PC,PE,ABS,PVC etc. |

| Cavity Number | 1*4, 1*6, 1*8,1*12, 1*16, 1*24, 1*32, 1*48 etc |

| Injection System | Pin gate, Submarine gate, Valve gate etc |

| Ejector System | Ejector sleeve, ejector pin |

| Cycle Time | Based on handle design |

| Tooling lead time | 30-60 Days |

| Mould life | At least 1.5million Shots |

| Quality assurance | ISO9001:2008/ CE certificate for European customers |

| Handle Mould Feature |

| 1. Adopt imported steel P20, Germany 2316, S136 etc. |

| 2. Each cavity and core have independent cooling system, BeCu add in the core of mold, shortening production cycle time. |

| 3. Rational mold design to extend mold life and get high production efficiency. |

| 4. Mirror hand polishing and mold plates chroming to create added-value. |

| 5. Precision Machining to ensure high production efficiency & fine parting line effect & Without flash on the ejecting pin trace after producing several years. |

| 6. Skilled Language in communication and experienced in international standard. |

| 7. Hot runner system: China advanced brand or imported hot runner system brand. Each cavity has independent temperature control and heater system. |

| 8. Different design handle mold based on customer's design. |