Bottle Cap Mould Manufacturers

Bottle Cap Mould Manufacturers

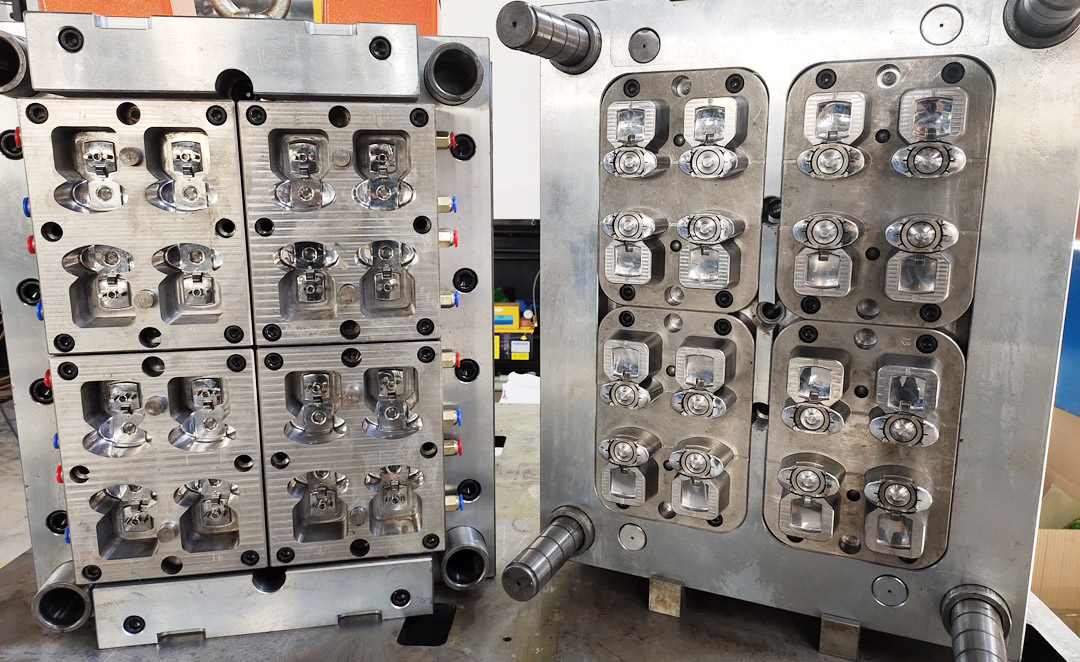

Taizhou Shuanghao Plastic Mould Co., Ltd.China Bottle Cap Mould Manufacturers and Bottle Cap Mould factory. We specialized in designing and manufacturing plastic cap mold, PET preform mold, blowing mold with our own mould factory.AD/CAM/CAE system for designing and engineering mould products.We design and use standard moul frame and use pricision 3D printer and CNC tooling machine to make parts, in order to ensure the quality of the moulds. We also wholesale Cap Mould, other molds and service.

Leak-proof design of bottle cap mould

Beverage bottle cap mold is made of PE (polyethylene) and weighs 2.9g. The outer side of the bottle cap body is evenly distributed with 120 anti-skid ribs to increase friction, and the top of the bottle cap has the brand name ZSM. An anti-counterfeit ring on the bottom of the bottle cap is connected to the main body of the bottle cap through eight small cylinders with a diameter of φ1mm and a height of 1mm. Inside the security ring, there are eight semicircular bosses with a uniform length of 3mm and a diameter of φ1.5mm. The inside of the bottle cap has a semi-circular thread and a security ring with a height of 4mm and a cross section diameter of φ1mm that closely matches the inner diameter of the bottle, while a security ring with a height of 1mm and a cross section diameter of φ1mm closely cooperates with the outer diameter of the bottle to prevent leakage.

As plastic bottle caps have the characteristics of strong plasticity, low density, high specific strength, bonding, high chemical stability, and various appearances, they are loved by more and more manufacturers and people. The demand for plastic bottle cap moldings is increasing, and the quality requirements are becoming higher and higher. This requires the development of molds for molding plastic parts, and the level of design and manufacturing must also be higher and higher.