Cap Mould with Cap Closing in the Mould System

Cap Mould with Cap Closing in the Mould System

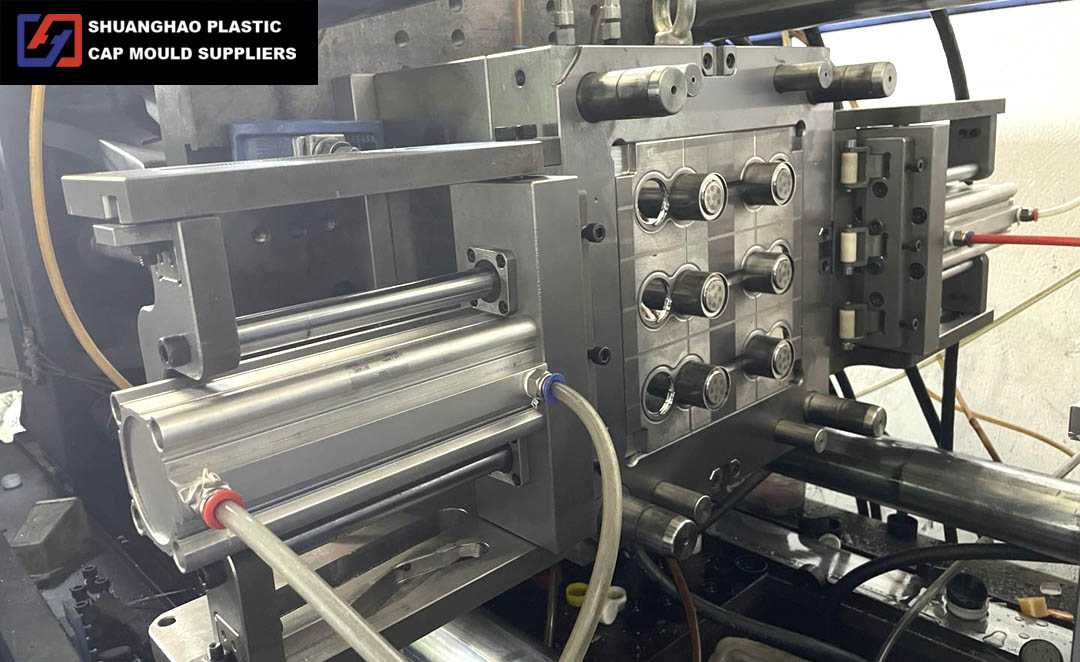

Flip Top Cap Mould With Cap Closing In the Mould System.

6 Cavity with Hot Runner System.

Ejector Sleeve Mould Structure.

| Technique | Plastic Injection Mould |

| Surface treatment | Polishing, or as customer's requirements |

| Material | Mold: 718H, S136H, NAK80, DIN1.2344, LKM2083, LKM2344, 8406, 8407, S136, LKM2767 etc. Product: PP, PC, PS, PE, PU, PVC, ABS, PMMA etc |

| General size | According to your 3d drawings |

| Design software | UG, PROE, CAD, CAXA etc |

| Plastic mould life | 500,000 shots |

| Manufacturing Machines | CNC,EDM,MILLING,WIRE-CUT, etc |

| Runner | Hot runner/Cold runner |

| Design Software | UG, PROE, CAD, Solid works, etc |

| Cavity number of mould | Single cavity, Multiple cavity or one mold with different products |

| Surface treatment | Words corrosion, Mirror polish, Frosted surface or textured surface |

| Mould standard | Domestic standard, HASCO standard, DME standard. Master flow standard |

| Mould testing | All of the moulds can be well tested befre the shipments. |

| Good packages | In strong wooden pallets to avoid any damages during the long transportation |