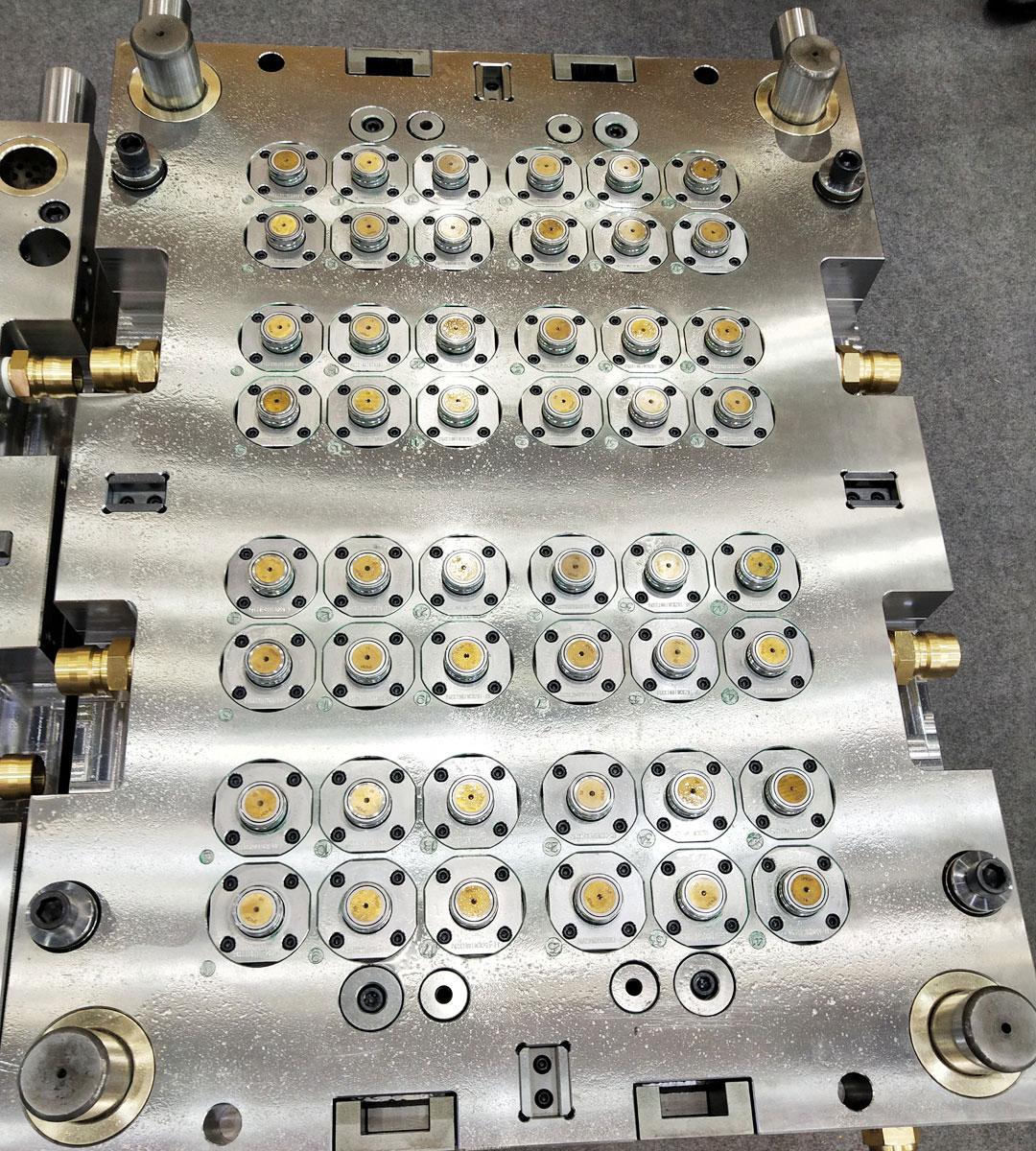

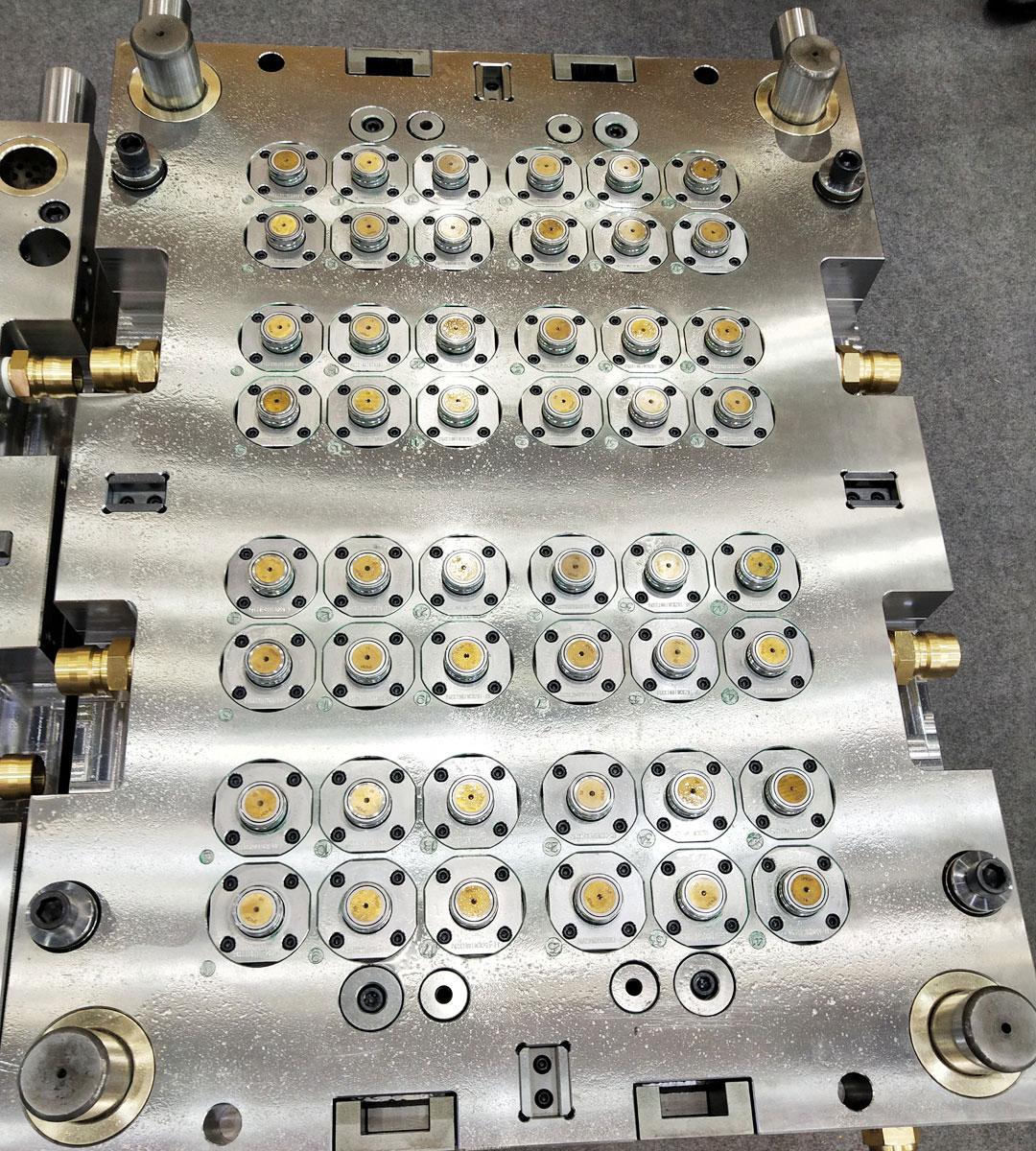

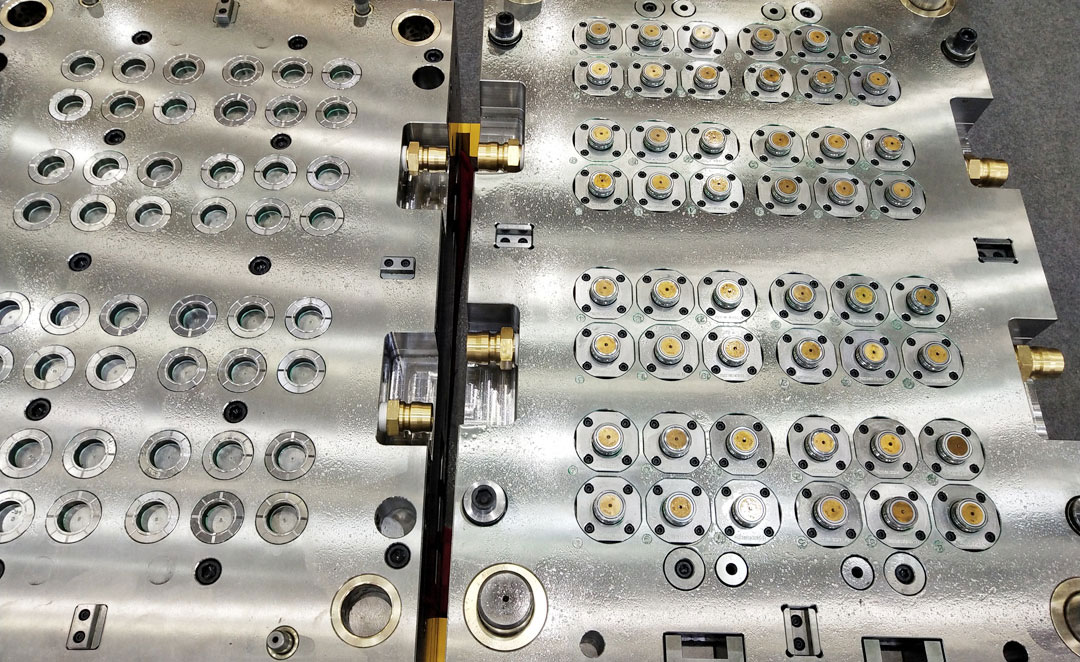

Injection Mold for a 48-Cavity Mineral Water Bottle Caps

1) Cap Mould : grinding→fly-cutter →CNC Milling→drilling→lathe→boring lathe→electric pulse →fine fly-cutter→polish→electroplate→install

2) Preform Mould: grinding→drilling→lathe→boring lathe→fine fly-cutter→electroplate→install

Business Steps

1. R& D We support customers' R& D. We'll make the files or improve the design if you need

2. Quotation Making Mould Quotation will be finished in 1 day according to information we get.

3. Negotiation The negotiation includes quality, price, material, delivery time, payment item, ect.

4. Mould Design We need to spend 3-5 days on mould and product 3D/2D drawing design

5. Mould We will build the mould based on customers' requirements. Before making the mould, we'll send mould design to get customers' approval first. Mould will be usually completed in 25-60 days

6. Mould Testing When moulds are finished, we will test the moulds to check if they will satisfy consumers' needs. And we will send samples for consumers' reference.

7. Sample shoot If the first sample come out is not satisfied by customers, we will modify the mould until it can meet customers' needs.

8. Delivery We'll delivery goods either by sea or by air, according to customers' requirements.