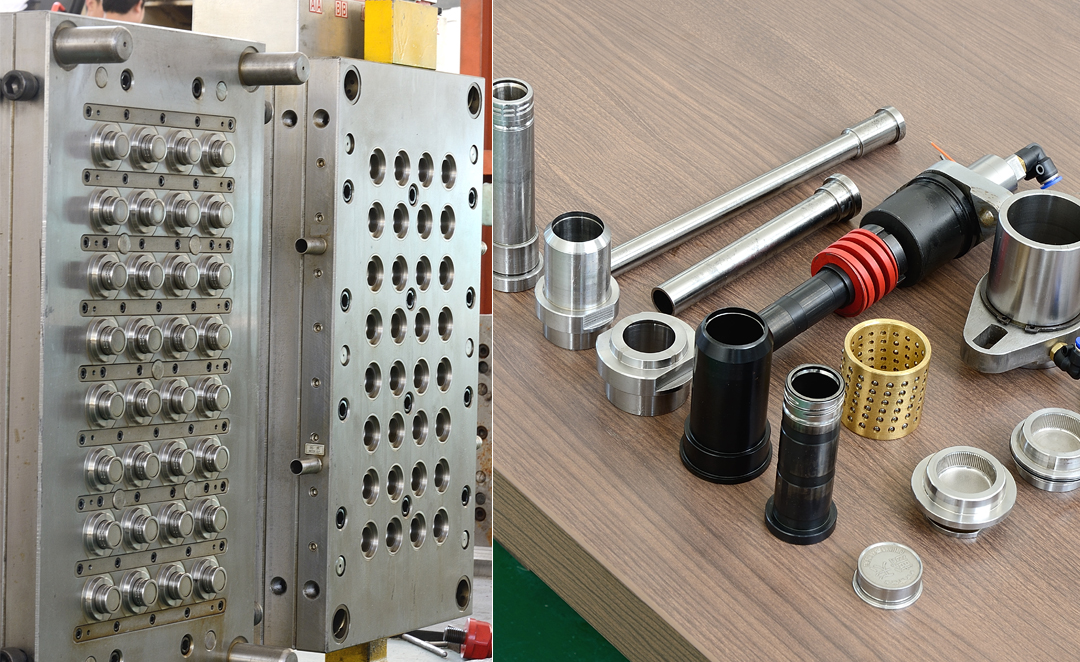

Mineral bottle water cap mould China Supplier Member

Key Specifications/Special Features:

28mm PCO water bottle cap mould specification:

1.28mm PCO water bottle cap mould core,cavity steel:ASSAB S136 and Austria M310

2.28mm PCO water bottle cap mould core sleeve steel: Japan DC11 or Austria W302

3.28mm PCO water bottle cap mould base steel :P20

4.28mm PCO water bottle cap mould core central ejector steel:Beryllium Copper and Chroming treatment

5.28mm PCO water bottle cap mould hot runner nozzle:America Beryllium Copper

28mm PCO water bottle cap mould design:

Advanced structure is designed consulting European cap mold.

Interchangeable parts for every cavity

All the heating elements of the mould is adopted quality famous brand from well-known supplier in domestic.

Point to point individually control the mold hot runner system.

High performance hot runner system ensures uniform melt flow and pressure in all cavities.

Moving part with high precise machining to make sure be interchangeable.

All of parts are manufactured by CNC equipment.

Mold cavity and Core are made of steel with fine polishing,high hardness and anti-corrosion to get mold's high precision and good quality.

Specifications

Mineral bottle water cap mould

1. The mould are employed Germany HOTSET Coil Heaters.

2. All cores and cavities are employed S316 stainless steel.

| Name | Description |

| Mould material | 45#, P20, S136,3Cr13/2316 etc. |

| Mould base | LKM, HASCO etc |

| Cavity | Single/multi |

| Runner | Hot |

| Design software | PROE, CAD, CAM,CAE etc. |

| Plastic material | PP, PE, PET etc. |

| Mould life | 500,000-3,000,000 shots/cav |

| Delivery time | 30-50days |

| Specification | Depends on customer's requirements. |

The mould are employed Germany HOTSET Coil Heaters.

1. All cores and cavities are employed S136 stainless steel, and the main plate is employed P20.

2. The delivery time is 50 days after receiving 40% down payment.

3. The mould packaging is adopted wooden box.