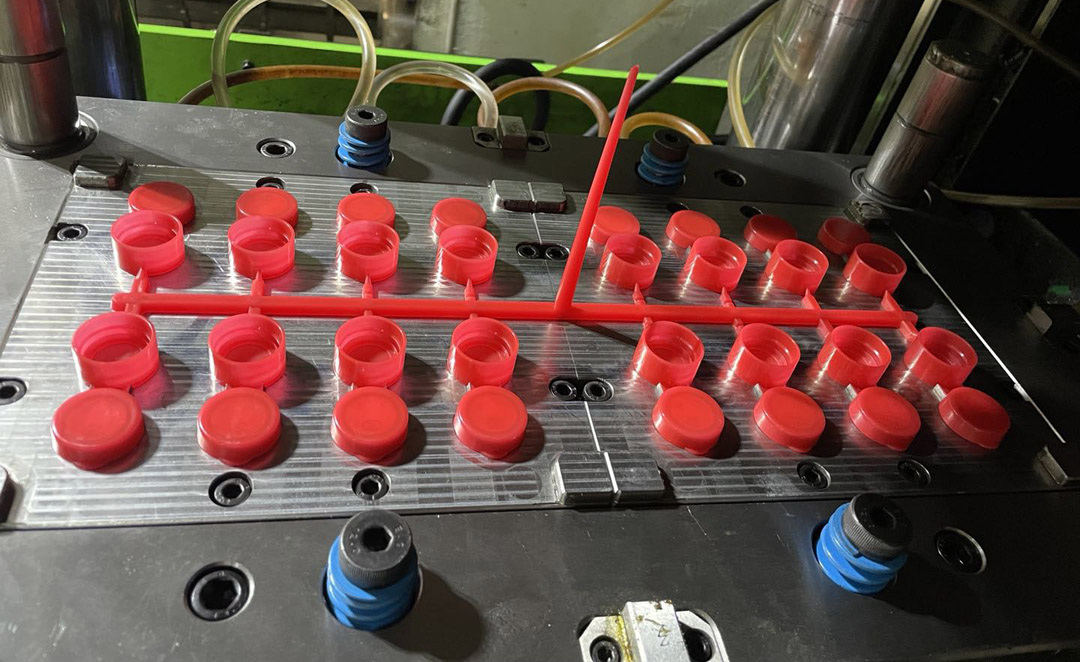

Oil Flip Top Cap Mould with Cold Runner system made

1.Samples/Drawing &Requirement from you

2.Mould design:we will Communicate and Exchange the opinion with you after you place order.

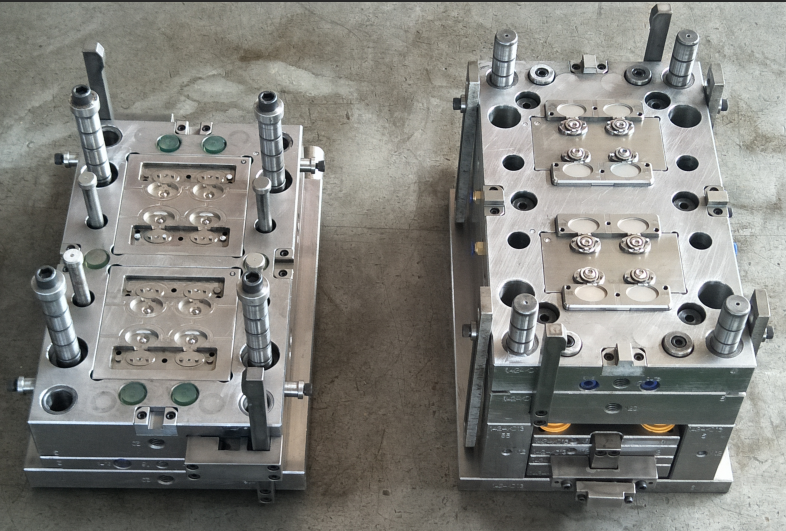

3.Material Purchase:Steel cutting and Mould base tooling.

4.Assembling.

5.Inspection of mould : following and controlling the tooling processing.

6.Mould testing:We will inform you the date.Than will send the sample's inspection report&injection parameters with the sample to you!

7.Your instruction &confirmation for shipment.

8.Ready made mould before packing.

| Technique | plastic injection mould |

| Surface treatment | polishing, mirror surface, frosted surface or texture surface |

| Material | mould : S50C , 718, P20, German 2316 , S136, 8407, AL7075

products: PP , PE , PET. |

| General size | according to ur 3D model (we have design team for ur customized product) |

| Design software | UG, PRO-E, CAD , SOLIDWORKS |

| Cavity number | Singer cavity , multiple cavities or one mould with different products |

| mould test | All moulds will be well test before the shipments |

| packages | Plastic film to avoid the water corrosion the mould and strong wooden case avoid any damages in the long transportation |