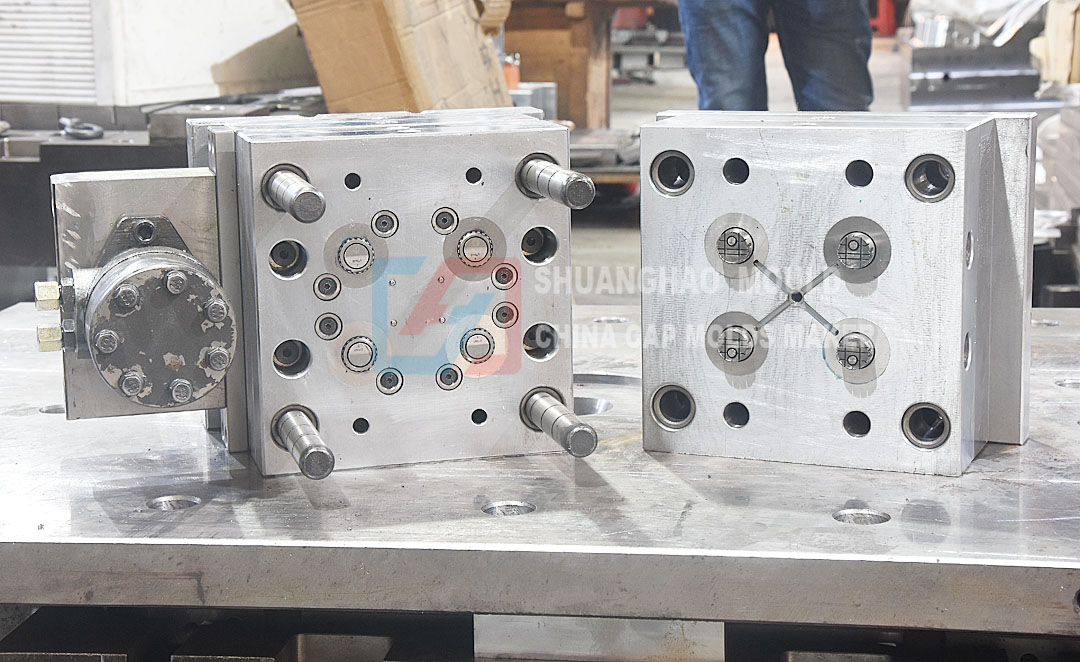

Plastic Cap Mould Manufacturer from China shuanghao

If you have your own injection molding machine, and prefer a cap mould to manufacture your own caps instead of buying finished caps, we are happy to manufacture the new mold for you. For almost all plastic caps we are selling on our site, the molds were made by ourselves.

The cap injection mold we can make for you include:

flip top cap mold, shampoo cap mold, condiments cap mold, disc top cap mold, screw cap mold, jar lid mold, child-resistant cap mold, tamper proof cap mold, pull-push cap mold, theft-proofing cap mold, easy tear cap mold, barrel cap mold, laundry detergent cap mold, cooking oil cap mold, wet tissue cap mold and so on.

The following are the details of our cap mould:

1. Mould ranges from 1 cavity to 72 cavities.

2. The mould bases made of stainless steel, and mould cavity and core adopt S136 with HRC 48-50.

3. Standard interchangeable mould components.

4. Before mold design, we will make the mold flow analysis report to make sure injection gate and position is in best situation.

5. We have a variety of plastic mold testing equipment, the quality inspection department carries out strict analysis and quality control on mold design, accurate to each part (tolerance control in +-0.05, precision control in +-0.001)

6. We have good management ability on product quality and tooling precision control. We have world-famous tooling machine tools, such as Sodick EDM, Fidia high performance milling center, DMG 5 axis high precision milling machine and so on.

7. We will run the cap moulds on injection machine for at least 2 hours to double check if the mould can run smoothly.

If you want to develop cap project, please kindly contact me, I am glad to share technical points and offer best price for you.