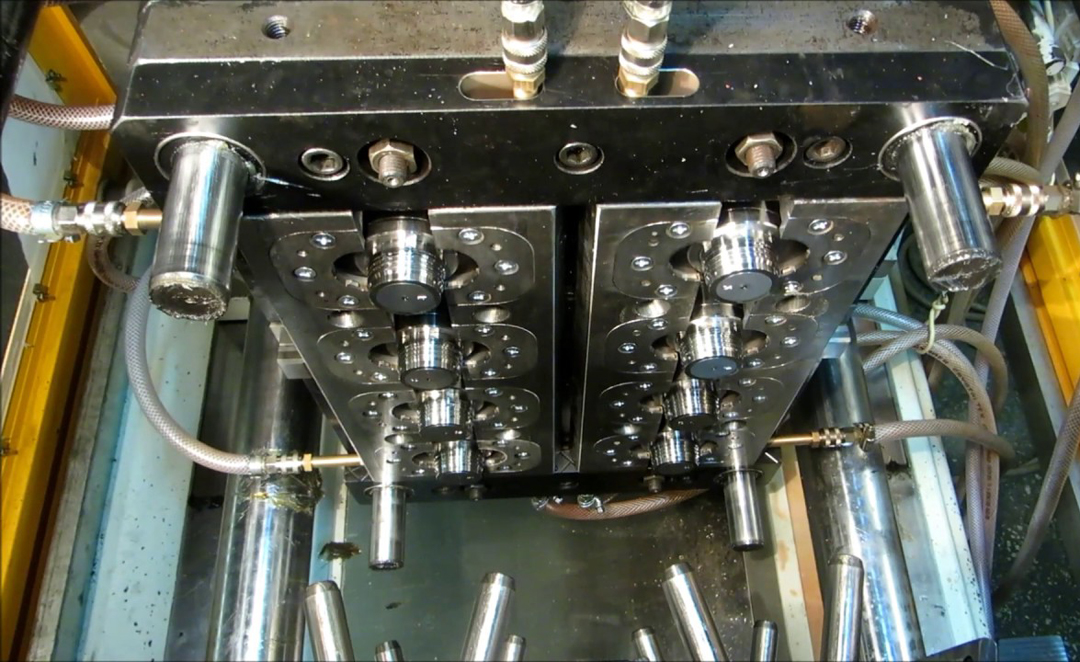

Focus on bottle cap mould products

Focus on bottle cap mould products.

1. Adopt the international advanced level special runner design.

2. The mold cooling adopts circulating water, effectively improving the mold efficiency.

3. The mould fastener adopts 12.9 high strength bolts.

We regularly produce cap mould and cap moulds for a variety of products from beverages, to medical devices, cosmetics, automotive parts, household items.

4. The sliding block adopts special pull rod structure, and the production efficiency of the product can be increased by 50%.

5. Mould body adopts imported S136 high quality die steel manufacturing, steel hardness HRC45-HRC48.

6. Medium-term modulation processing, after tempering, nitriding treatment, make the tool has good comprehensive mechanical properties, big stiffness, small deformation,

How do I check the mould?

Welcome to visit us for mould inspection on site, if you don`t have free times,

We provide you the final samples for further checking, at same time we show you the mould test

video with around 4mins.

What is term of serive?

Warranty Time: One year warranty, or 2millions for our PET preform moulds and cap moulds

Service Time: Provide 24hours Pre-consultation and after sale serive.

Technical support: Provide lifelong and free technical support and maintenance services.

Mould repair service:

1. Make new spare parts for replacement, during the warranty time is free.

2. We will provide all mould parts for whole life of mould if needs.

Because we have saved drawing for each part of mold to provide mould parts for customers.

Shuanghao Molds services injection molding clients in the Caps, Closures, Cosmetics, Food Packaging, Medical and Thin Wall Containers. We offer complete "art to part" services that include plastic product design/development, prototype and production molds. Our specialty is highly complex, multi-cavity high efficient production molds that require fully interchangeable components.