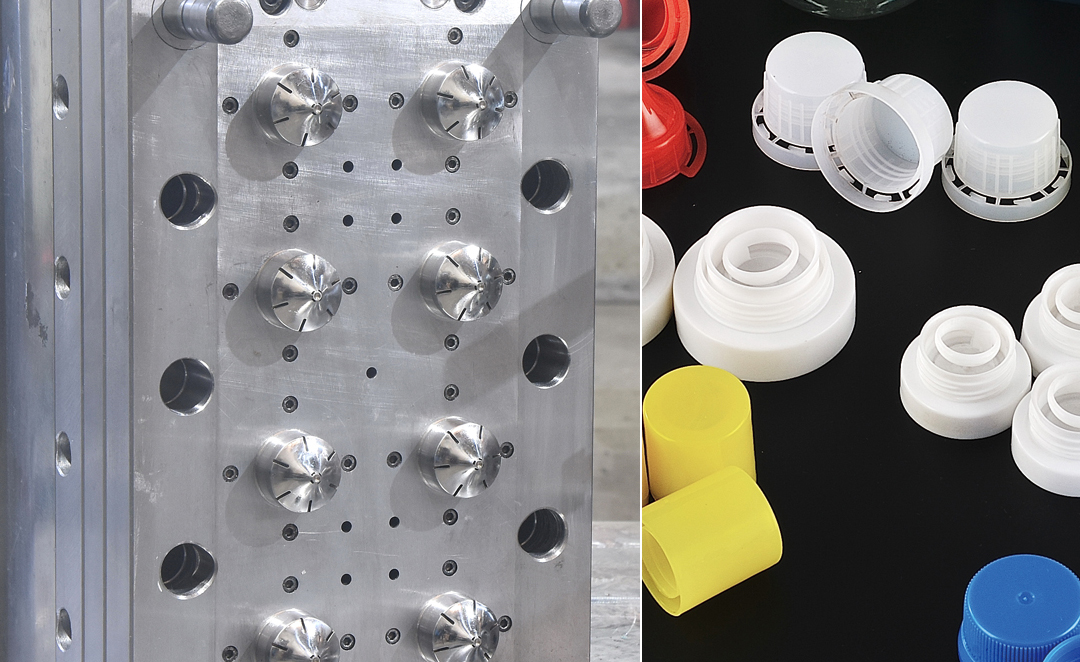

High Quality Durable Customized plastic mould making bottle cap injection mold

Our advantages:

1.Rich experience in mould making.

2.Excellent R&D team.(We can offer you 3D mould design with all details within one day.)

3.Efficiency production department.(We can finish mould within 45days.)

4.Competitive price in save level of mould manufactuers.

| TECHNICAL SPECIFICATIONS | |||

| Type Of Mould | Injection Mould | Small, Medium, Large Mold | |

| Mold Material | S136, P20, 718H , 2738 , NAK80 ,1.2311 Etc | ||

| Nr of Cavities | 1+1,1+2+1,2+2,4+4, Single Or Mutilcativies | ||

| Cycle Time | 10-30seconds | ||

| Injection Machine Weight | 90-1000ton | ||

| Life Span Of Mold | 300k-1000k | ||

| Shrinkage | According To Material | ||

| Product Material | PE,PP,HDPE,PPR,PVC,PP,PS,PET,ABS,PC,Etc | ||

| Injection Type | Hot Runner/Cold Runner | Hot Sprue, Sequential Injection/QTY Of Drops | |

| Gate Point | Edge gate, Pin point gate, Sub gates, Fan gate, Bayer | ||

| Ejection | Round Ejector Pin | ||

| Slider | Outer, Inner Slider, Lifter | ||

| Surface Finish | Tech Polish, High Gloss, Texture, VDI 3400 | ||

| Mould Hot Treatment | Tempering , Quending , Nitriding | ||

| Main Processing Equipment | Sodick, Seiki, CNC , High Speed Carve , EDM ,Wire Cut , Drill | ||