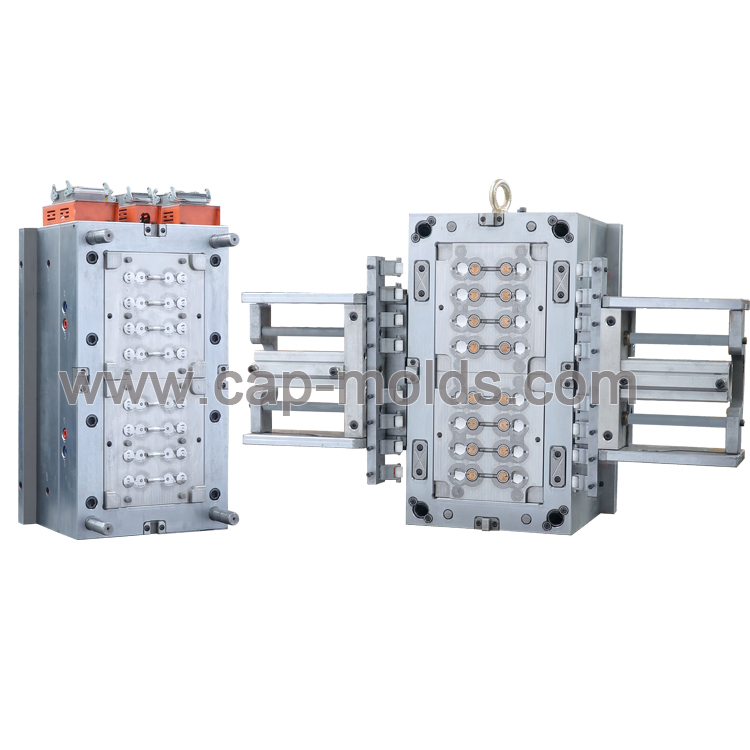

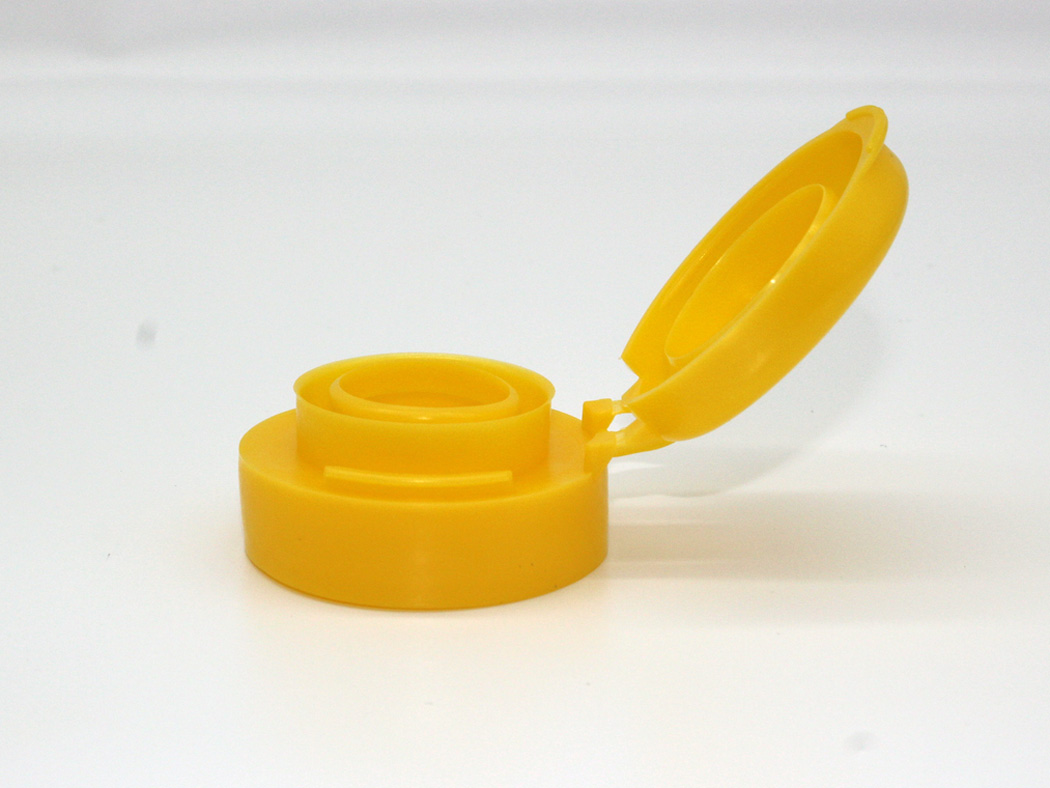

Flip Top Cap Mold Shampoo Cap Mold

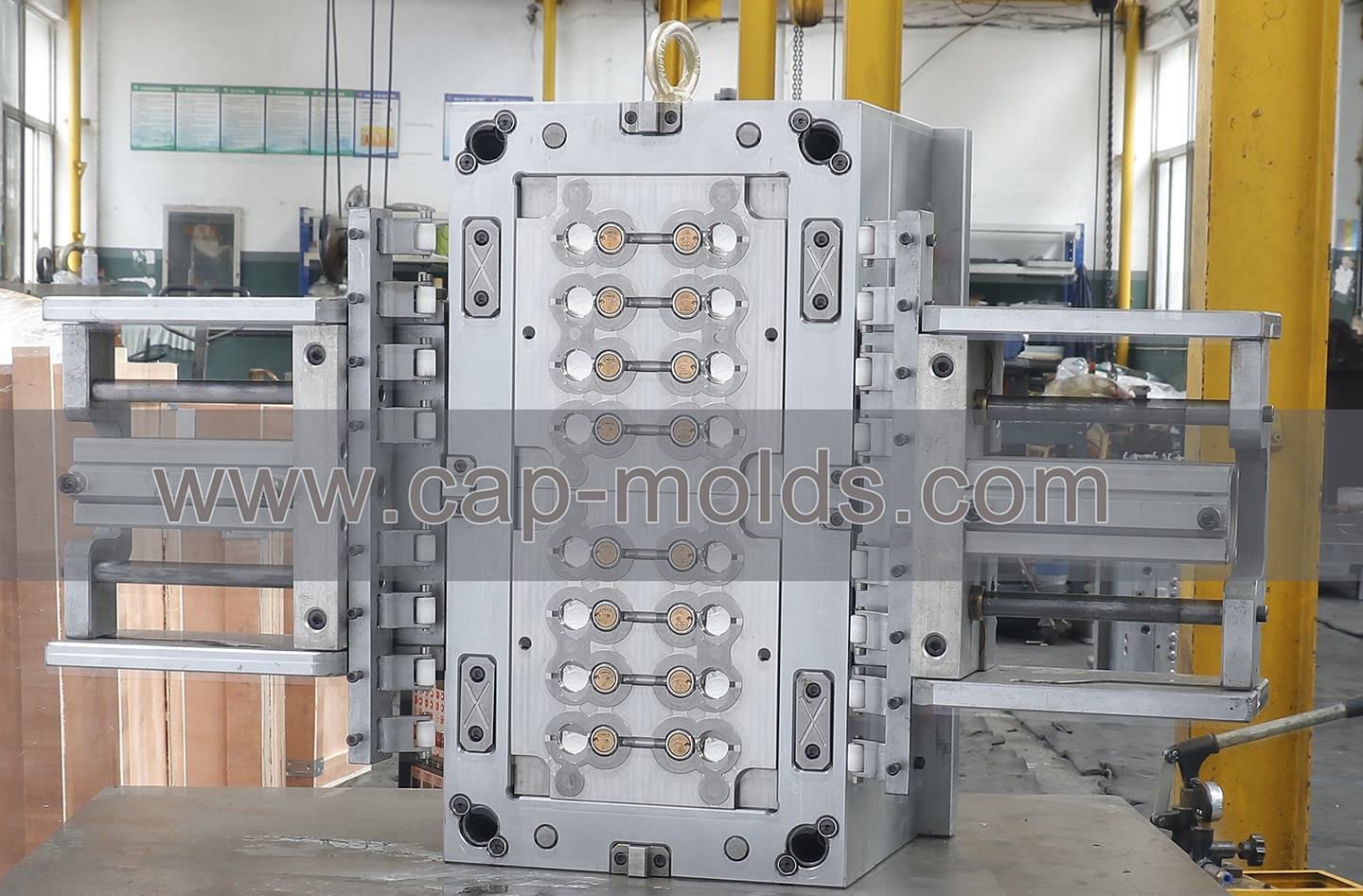

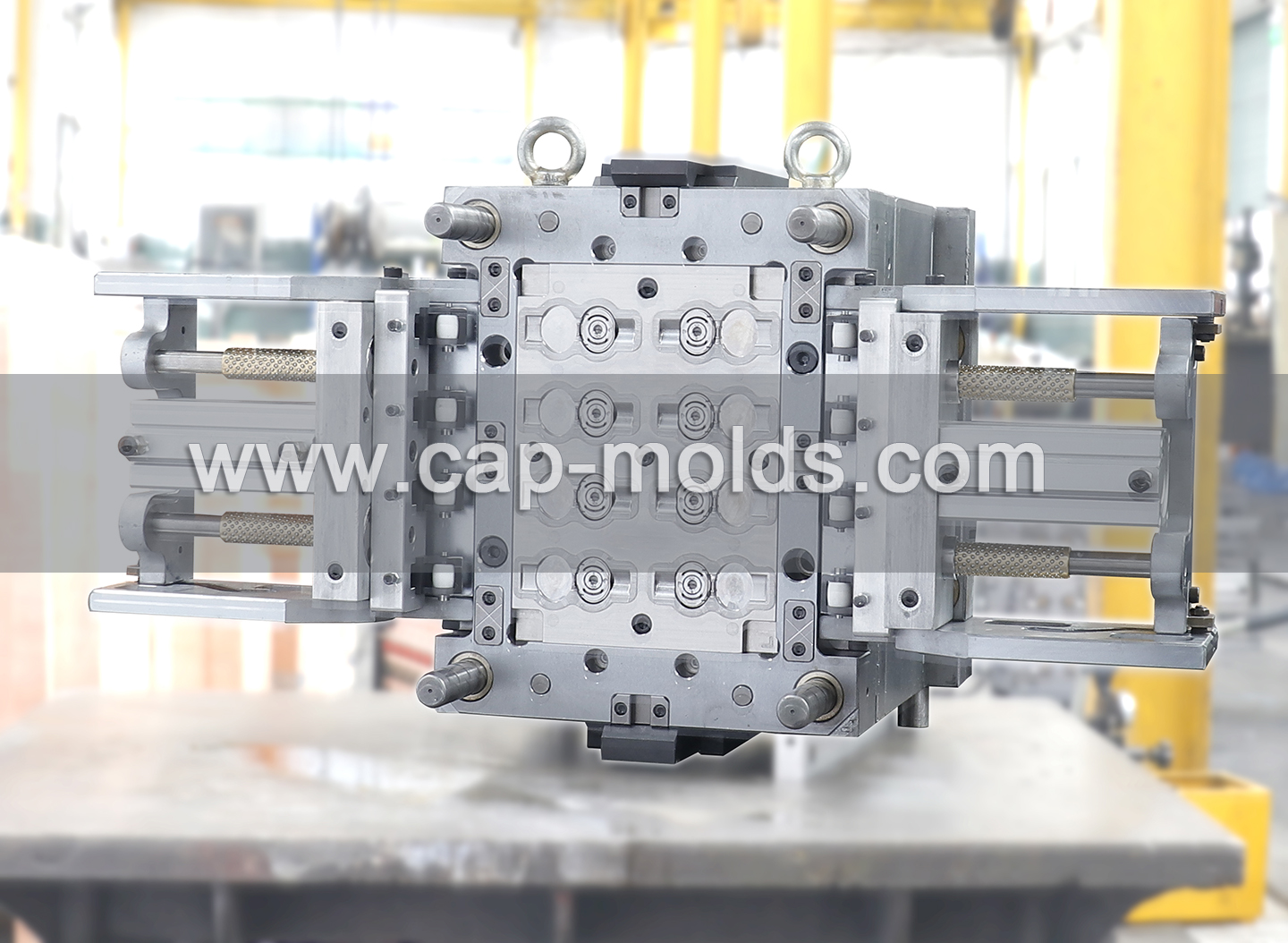

FLIP TOP CAP MOULD SPECIFICATION:

| Mold name | flip top cap mould |

| Cavity number | single/multis or customer's requirement(ranges from 1 to 32cavities) |

| Runner syster | hot runner / cold runner |

| mold core/cavity material | S136,2316, H13, 1.2344 or as customer's requirement |

| Mold base material | P20 ,718,2738,H13 or as customer's requirement |

| Mold structure | Ejector system, in-mold closing system,unscrewing with hydraulic motor , locating position system |

| design software | PROE , Cimtron,UG,AutoCAD,CAM,CAE,UG,ect |

| Hot runner | Hot runner made by our own factory. YUDO,SINO,HUSKY or other famous brand as your choice. |

| Mould surface | Texture/Mirror polish or according to customer's request |

| Mold Guarantee time | 3 million shot times |

| delievery time | 25-50days after get the deposit |

- Description

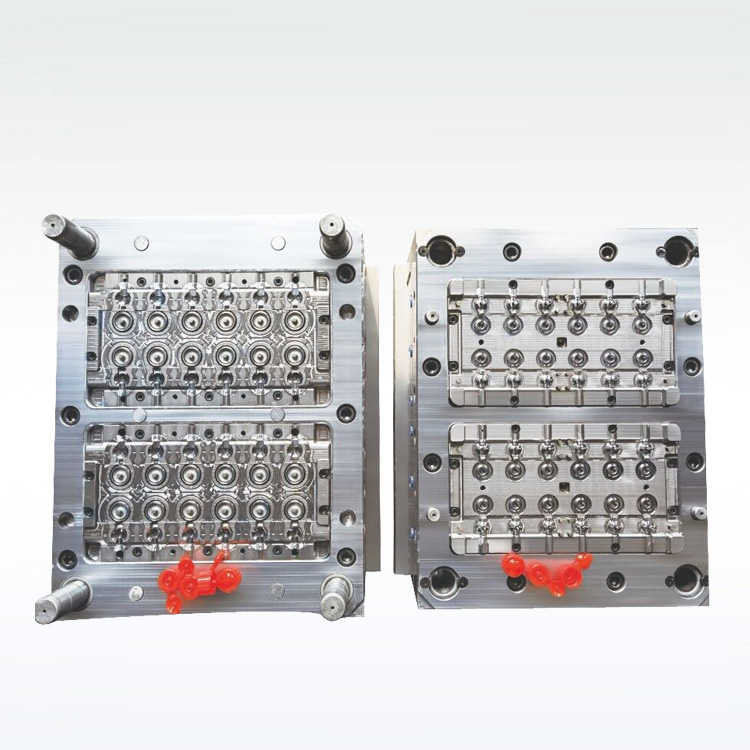

Cap mould specification

| Name | cap mould |

| Mould Material | NAK80,S136,2316,2738,H13,5CrNiMo,718H,P20,40Cr,60#,45# etc |

| Product Material | PP,PE,PC,PA,PS,PU,PVC,PMMA,ABS etc |

| Cavity No. | Single or multi |

| System Of Runner | Hot runner,Cold runner,Pin-point gate,Submarine gate, etc |

| Ejector Type | Ejector pin,Air gate,Ejector plate,Hydro-cylinder,etc |

| Term Of Mould Production | 20days- 30days |

| Guaranteed Number Of Cycles | 300,000-3000,000 closing |

| Mould Design Software | Ug,Proe,Solidworks AotoCAD,Moldflow,ect |

1. Specialized in manufacturing plastic injection mould and Bottle Cap Mould .

2. Good quality Bottle Cap Mould manufacturer

3. Competitive price

4. Punctual delivery time

5. High precision Bottle Cap Mould

6. Good after-sale service

Our Trade process:

1.R&D Customers provide the bottle cap design or samples for us

2.Negotiation Mutual discuss for the materials ,the price ,delivery time etc

3.Place the order Strictly do according to the order to meet our customer needs

4.Mould Design confirmation by our customer-Mold making strictly by the design

5.Sample Trial sample-our customer confirm -move forward to batch production

6.Delivery Delivery could according to our customers required by sea