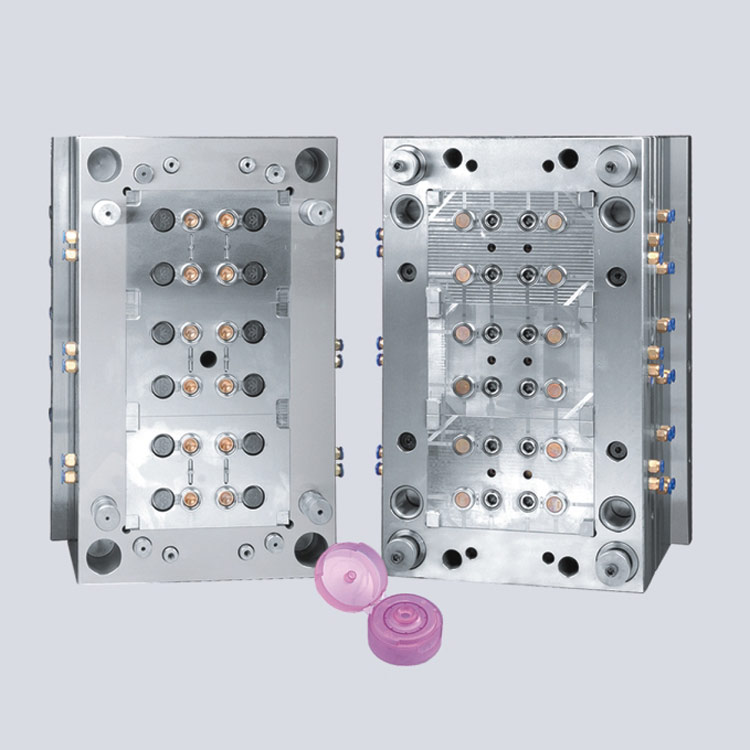

12 cavity Flip Top Cap Mould

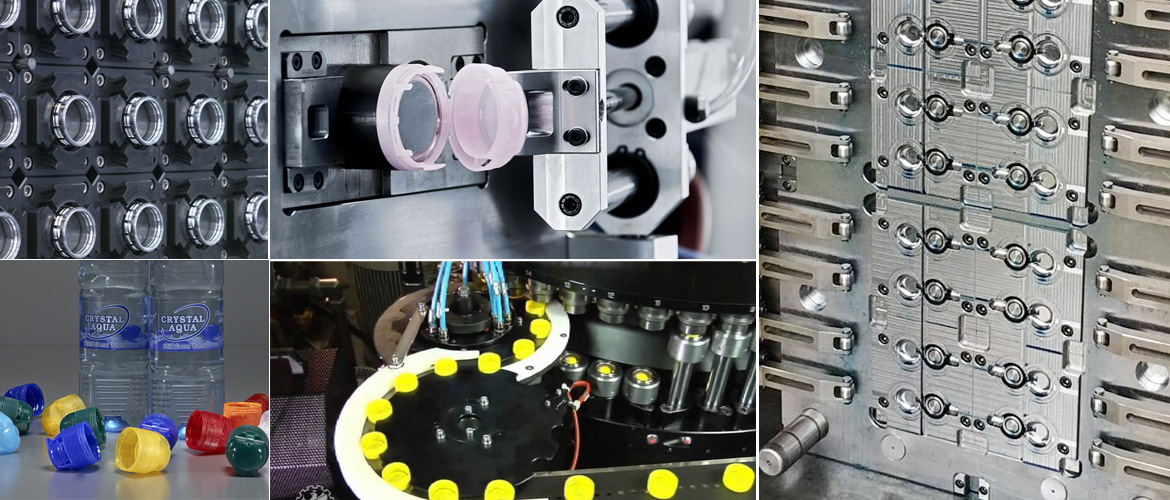

Flip Top Cap also know as Flip Top Caps & Cap mould Stopper Cap is one of type closure used for Plastic Bottles. Flip Top Plastic Bottle Caps were used in packaging Hand sanitizers, Baby shampoo, Hair oil, and other essential oils. Intiallialy it was used for beer & mineral water but nowadays it was used by ayurvedic and herbal formulation manufacturers, lotions, shampoos, and tomato ketchup producers.

Invented by Charles de Quillfeldt (United States) who filed a patent on 30 November 1874 & got it in the year 1882. Later on, he created many more varieties of Plastic Bottle Caps.

| Cavity | 12 |

| Mould base material | P20, 420 etc. |

| Core, cavity, neck | S136, 2316, SKD61 etc. |

| Surface treatment | High polish |

| warranty | 1 year without man-made |

- Description

| Location: | TAIZHOU,CHINA |

| Business Type: | Manufacturer, Exporter |

| Model: | Plastic mould and machinery |

| Delivery method: | By air, By sea, By express. |

| Minimum order quantity: | 1PC/SET |

| Price: | Consultation |

| Packing details: | Standard export packing way |

| Delivery time: | 30-60days |

| Payment method: | TT,LC,Paypal,Westen Union |

● Plastic Flip Top Caps Injection Mold Cavity:4 & 8 & 16 Cavities.

● Plastic Flip Top Caps Injection Mold Main Material:SUS420 HRC50˚±1˚.

● Plastic Flip Top Caps Injection Mold Injection System:Cold Runner System.Hot Runner System (Taiwan Brand).

● Plastic Flip Top Caps Injection Mold Ejection System:Ejector Pin & Stripper Plate & Two Steps Ejector.

● Plastic Flip Top Caps Injection Mold Cycle Time:10 ~ 18 ± 2 Seconds.

● Plastic Flip Top Caps Injection Mold Running:1 year Guarantee; Shots guarantee 1 million under the normal operation and period maintenance.

● Plastic Flip Top Caps Injection Mold Delivery Time:80 ~ 100 working days to T1 sample delivery.

● Plastic Flip Top Caps Injection Mold Features:High Polish.

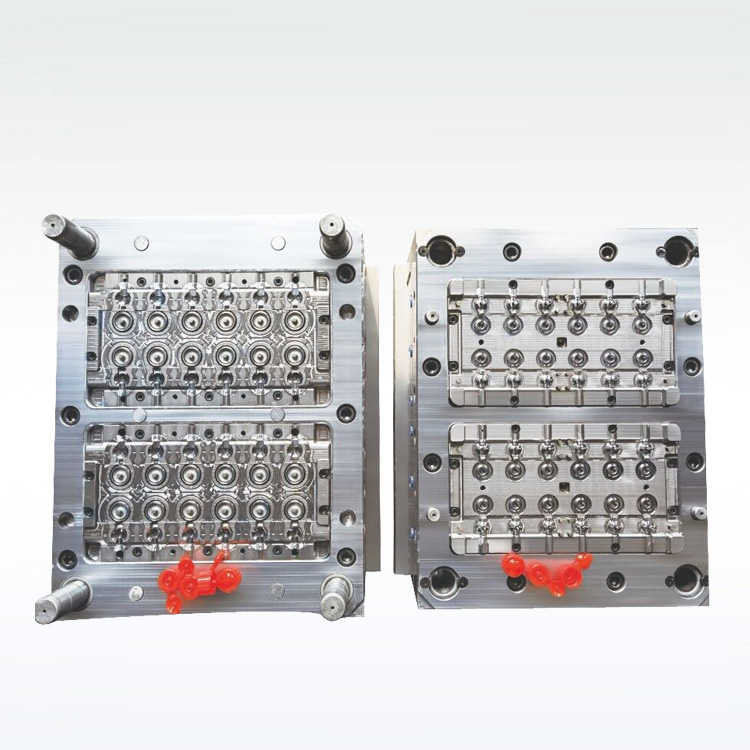

1. Product Specification

| Place of origin | China |

| Cavity | 8 |

| Mould base material | P20, 420 etc. |

| Core, cavity, neck | S136, 2316, SKD61 etc. |

| Surface treatment | High polish |

| warranty | 1 year without man-made |

1.The mold plate is made of stainless steel.

2. Mold ranges from 1 cavity to 72 cavities.

3. Standard interchangeable mold components.

4. High performance hot runner system ensures uniform melt flow and pressure in all cavities.

5. All of parts are manufactured by CNC equipments.

6. Advanced structure is designed consulting European cap mold.

7. Mold cavity and Core are made of steel with fine polishing, high hardness and anti-corrosion to get mold's high precision and good quality.

8. Pneumatic drive the nozzle pin for simultaneous high-speed open and close actions.

9. Patent designed rectifying system is adopted to lessen the possible preform thickness problem happening during production.

10. Special designed water hoses eliminate leakage and water marks on preform.

11. Mold flow analysis reduce AA level.

12. Long using life over 2.5 million times of injection cycle.

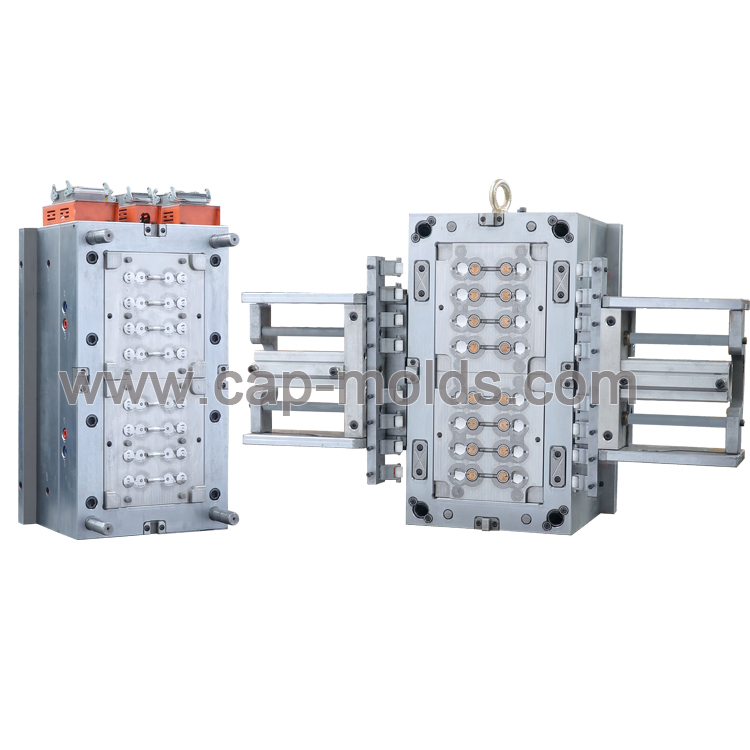

Product Name | China Taizhou Fashion Design Hot Selling Shampoo Detergent Bottle Plastic Injection Flip Top Cap Mould |

| Cavity&Core Stee | P20H,718H,2738H,S136,H13 etc. |

| Product Material | PP,HDPE,LDPE etc. |

| Mould Base | LKM,ISM,HASCO,DME |

| Cavity | 8 cavities |

| Mould life | 500,000 ~1million shots |

| runner type | cold/hot runner |

| Delivery time | 30~60day |

| The main Mould Steel and Hardness for you reference: | ||||||||

| Steel Grade | S50C | P20 | P20HH | 718H | 2738H | H13 | S136 | NAK80 |

Hardness(HRC) | 17-22 | 27-30 | 33-37 | 33-38 | 36-40 | 45-52 | 48~52 | 34-40 |

| Flip top cap mold | |

| 1.R&D | We support customer R&D. Make the files or improve the design if you needed. |

| 2.Quotation Making | Mould Quotation will be finished in 1 day according to information we get. |

| 3.Negotiation | The quality, price, material, delivery time, payment item, etc. |

| 4.Mould Design | 1-2days for product 3D/2D drawing design as per customer's design or our company's design. Then in further make the mould 2D/3D design. |

| 5.Mould | 1.confirm the proucts and the mold design |

| 2. Mould material prepare | |

| 3. Rough machining(heat treatment on mold base and pre-harden on mold) | |

| 4. CNC/ Vacuum Hardening on mold main spare parts | |

| 5. finishing machining( JDPAINT, DEM.etc) | |

| 6. Dimension inspection | |

| 7. Ejector& runner& cooling & other device process | |

| 8. Assemble mold | |

| 6.Mould Testing | When moulds are finished, we will test the mould and we will send samples for consumer reference. |

| 7. Sample confirmation | If the first sample is not satisfied by customer when it is come out. We modify the mould and until meet customer’s satisfaction. |

| 8.Delivery | Delivery goods by sea or by air, according to customer’s requirement. |